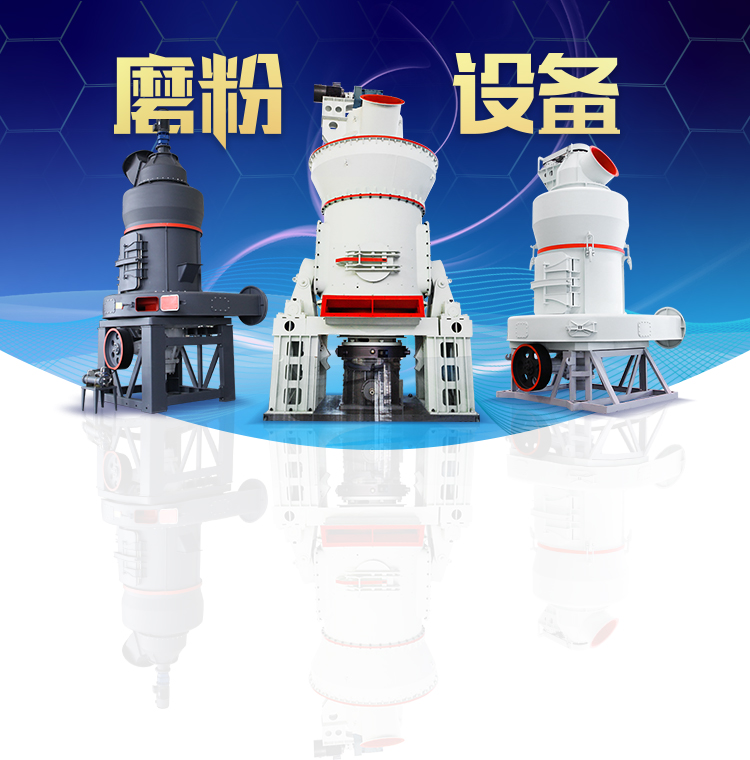

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Roller Mill Installation Sequence

.jpg)

Vertical roller mill for raw Application p rocess materials

2016年1月4日 The vertical roller mill has high energy efficiency and the installation space is smaller compared with tube mills These days, the vertical roller mills have been widely 2022年4月4日 The quadropol® vertical roller mill by thyssenkrupp Industrial Solutions takes a holistic approach to modern grinding systems in terms of its simple and compatible design VERTICAL ROLLER MILLS A holistic VRM approach3 天之前 The production of Portland Cement (OPC, CEM I) with Vertical Roller Mills can demand the following benefits from a Grinding Aid: ́ Increased production rate, energy saving ́ Higher SikaGrind® for vertical roller millsVertical roller mill – digital solutions and services In recent years, thyssenkrupp Polysius has successfully continued step by step the development process for the quadropol® vertical roller mill concept This compact and modular concept quadropol® thyssenkrupp Polysius Grinding

.jpg)

Chapter 7 Roller Milling of Wheat ScienceDirect

2007年1月1日 Breakage of wheat kernels during roller milling has been modelled in terms of the distribution of kernel characteristics (hardness, size, moisture) and roller mill operation (roll 1996年4月18日 While other competing technologies exist, notably the vertical impactor, the vertical roller mill, and most recently the Horomill, none of these has become common in North Selection and installation of a vertical roller mill for clinker 2004年4月30日 A new vertical roller mill installation concept [cement industry] Abstract: Ciment Quebec Inc is located in St Basile, Quebec, Canada The company have embarked on a A new vertical roller mill installation concept [cement industry A vertical roller mill has been installed in a Canadian cement plant for the pregrinding of Portland cement clinker It is the first application of this type of technology in the Western Hemisphere Selection and installation of a vertical roller mill for clinker

Cement mills and raw mills for high throughput rates Gebr

With this new type of roller suspension, the rollers can be swung out of the mill in a controlled way – for ease of replacing the onepart grinding roller tires The segmented wear parts of the 2017年8月12日 For over 100 years the company Loesche has been building vertical roller grinding mills for grinding: Coal Cement raw material Clinker / granulated slag Industrial PROCESS OPTIMISATION FOR LOESCHE GRINDING With this new type of roller suspension, the rollers can be swung out of the mill in a controlled way – for ease of replacing the onepart grinding roller tires The segmented wear parts of the grinding table are replaced, using a lifting device and the maintenance drive Moreover, the rollers can be swung out separatelyCement mills and raw mills for small to medium throughput 2024年8月27日 Installation Sequence 6 EATON Aerospace Group TF10048D May 2014 1 Roller Swage Machines Eaton’s manual 4777PLC1 Roller Swage is capable of swag Part Number Mandrel Part Number Roller Part Number Cage Part Number Material To Be Used 732004016 732104016 732204016 732304016 732006019 732106019 732206019 7323 Internal Roller Swage Tooling Equipment Eaton

Roller Mills • Alvan Blanch 2024

Installation Options: Mixer Frame: To position mill onto Alvan Blanch mixer Support Stand: For independent operation with side chute or screw discharge Because the rolls are the working surfaces of any roller mill, extra money 2016年1月4日 The vertical roller mill has high energy efficiency and the installation space is smaller compared with tube mills These days, the vertical roller mills have been widely adopted A)Structure (1) The rollers are hydraulically pressed against a disc table and the feed is ground between the rollers and the disc tableVertical roller mill for raw Application p rocess materials2023年5月31日 How many rollers are used in a rolling mill? The quantity of rollers employed in a rolling mill varies based on the specific application and the desired final product Rolling mills can have two to several dozen rollers arranged in a specific configuration Common roller configurations include twohigh, threehigh, fourhigh, and cluster millsA Definitive Guide to Rolling Mills: All You Need to Know2021年4月20日 The roller mills increased the capacities of flour mills, as well as amount, diversity and quality of flour and speed up the milling process compared to millstone ground operation resulting in lower material and installation costs, lower pneumatic system air requirements resulting in lower energy costs and lower filter surface requirements The Evolution of Milling Process SpringerLink

.jpg)

Bearing installation and maintenance guide SKF

2023年12月19日 Bearing Installation and Maintenance Guide This catalog is intended to be used as a product reference guide only and as such contains only very basic information This catalog is not CARB ® toroidal roller bearing Spherical roller thrust bearing Y bearing 10 11 Mounting and dismounting of bearings General information2021年3月12日 BALL MILLS 1 FEBRUARY 2021 INTERNATIONAL CEMENT REVIEW T here are currently several energyefficient grinding systems available for the cement and mineral industry, including vertical roller mills (VRM), highpressure grinding units (HPGR) or simple roller presses, as well as the most traditional type of installation: ball mills, combined inBALL MILLS Ball mill optimisation Holzinger Consulting2020年7月13日 Singleroller mills Singleroller mill EW 50/40 EW 50/60 EW 65/40 EW 65/60 Dimensions (W x H x D) mm 1300 x 1100 x 3400 1750 x 1100 x 3400 1300 x 1400 x 1620 1660 x 1400 x 2480 Weight kg 1410 2150 2450 3720 Motor kW 11 15 15 185 Roller size (Ø x W) mm Ø500 x 400 Ø500 x 600 Ø650 x 400 Ø650 x 600 Gap width, min – maxJaw crushers and roller mills SIEBTECHNIK TEMABühler roller mills consistently and safely grind wheat, corn, rye, barley, spelt and other grains We offer a wide range of roller mills and optional functions MRRK is stable and reliable, easy to operate and fast and simple to install Roller mill Roller Mills Milling Bühler Group

Loesche vertical roller mills for the comminution of ores and minerals

2001年10月1日 LOESCHE vertical roller mills are widely used for the comminution of raw materials in the cement industry, for the comminution of clinker and blast furnace slag and for the production of pulverized coal for cement kilns, blast furnaces and power plants Superimposed on the coastal clastic Cainozoic orebearing sequence is a calcium 2023年10月20日 This is critical to ensure that the roller grinder shuts off if the one of the components downstream stops running for any reason Amp Meter Box We highly suggest you install an amp meter box on your mill to prevent Electrical Grain Mill Manuals2018年4月23日 For Hydraulic Roller Cam Valve Spring Installed Height: 1800” Valve Spring Seat Pressure: 150 lbs Max Valve Lift: 575” (Coil Bind @ 650”) Replacement Spring PN 5845 8 4 5 9 7 3 2 6 10 Figure 1 Tightening Sequence 1 Installation is the same as for original equipment cylinder headsPERFORMER RPM ALUMINUM CYLINDER HEADS2024年8月10日 In the rolling process, the job is drawn through a set of rolls due to interface friction, and the compressive forces reduce the thickness of the workpiece or change its crosssectional area The types of rolls used in rolling mills depend upon the shape, size, and gap between the rolls and their contour Because of workability and limitations in equipment, rolling Rolling Mills: 6 Different Types of Rolling Mills [Images PDF]

Vertical Roller Mill Operation in Cement Plant

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing processIn recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etc The VRM cement mill has a 2023年10月20日 It is recommended to anchor the mill stand using Grade 5, 1/2" concrete anchors at a minimum thread length of 11/2" Anchor depth may vary based on application Anchors should be torqued to approximately 40 ft lbsFeed Mill Grain Mill Manuals RMS RollerGrinder2023年12月4日 21 Vertical Roller Mill The VRM shall have three or four rollers and a table The rollers were pressed against the ore and table using hydraulic cylinders during operation The table is rotated by an external drive train, and rollers are counterrotated due to the friction between the roller and materialNumerical Investigation of Vertical Roller Mill Operation In the context of rolling mills, Industry 40 integration allows for seamless connectivity and data exchange between different manufacturing systems The advantages of Industry 40 integration are farreaching Realtime monitoring and communication between various components of the rolling mill facilitate datadriven decisionmakingModern Rolling Mill Technology and Their Advantages

Crushing roller mill for the industry AMANDUS KAHL

The speed of the rollers and the grinding gap can be adjusted during operation Our crushing roller mill WSB is very appropriate for grain and other feed components Process sequence Two corrugated and counterrotating rollers with different rotating speeds crush the respective product2022年5月2日 Start up Sequence of Vertical Roller Mill Free download as PDF File (pdf), Text File (txt) or read online for free The document outlines the startup sequence of a manufacturing process It involves starting raw material Start Up Sequence of Vertical Roller Mill PDFOur bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency It is affordable to install and cost effective to operate over your cement plant’s lifetimeOK™ Raw and Cement Mill FLSmidth Cement2017年8月28日 the horsepower as the width of the mill in inches A 42 in mill is typically driven by a 75 hp motor; 48 in mills by 100 hp motors; and 60 in mills by 125150 hp motors If a variety of compounds are processed (as is increasingly the case), it is very helpful to install a variablespeed DC driveMill mixing Springer

(PDF) Design and Realization Of Roller Mill Control System

2012年12月31日 Mikael Maasalo suggests that pulp mill power production can be increased by automating and integrating the lowpressure setpoint so that it slides according to mill steam use2022年5月17日 Maintenance and overhaul of bearings Under the condition of correct installation of rolling mill roller bearings, the quality of their normal working process and periodic overhaul is of great importance to the troublefree operation of the entire production line, and relevant departments and personnel must pay attention to themWhat is the operating Instructions for Installation, Use and 2014年4月1日 Two mill systems are employed for most coal grinding applications in the cement industry These are, on the one hand, vertical roller mills (VRM) that have achieved a share of almost 90% and, on (PDF) The latest innovative technology for vertical roller mills 1 Introduction The vertical roller mill (VRM) is heavy mechanical equipment that used in the cement materials industry to process cement, slag, and coal cinder (Pani Mohanta, Citation 2015)The equipment always needs to work in the environment of heavy load, high temperature, high pressure, high corrosiveness, electromagnetic radiation interference, and multifield Full article: Reliability assessment of the vertical roller mill

Motor Startup Sequence Grain Mill Manuals RMS Roller

2023年10月20日 Motor Wiring Diagram and Starting Sequence Note: Motor wiring orientation is determined upon whisch set of rolls draws the amps from each motor, not the physical location of the motor on the mill! Double Pair starting sequence Triple Pair starting sequence Quad Pair starting sequence2019年4月17日 Typical multi level FCM Mill installation High pressure twin screw with pelletizing head ( up to 200 Bar(2900 psi) First stage (masterbatch ) Batch mixerconvex with pellet head Followed by dewatering / drying conveyor and storing bin/drum Second Stage ( remill or final mix) Continuous mixer followed by mills or convex with roller head then millRubber Mixing Equipment; Past, Present, and Future2019年6月29日 OK mill Ball mill OK mill Ball mill OK mill Ball mill 3 days 155 145 225 220 115 110 7 days 255 245 275 260 195 190 28 days 430 420 350 330 425 425 *50/50 clinker and slag mixture Portland cement Slag* RollerTable Table Roller Without hardfacing1 1 65 With hardfacing05 3005 25 *50/50 clinker and slag mixtureOK vertical roller mill Environmental2024年3月16日 A new vertical roller mill installation concept [cement industry] Free download as PDF File (pdf), Text File (txt) or read online for free The document summarizes the history and upgrades of the raw material grinding A New Vertical Roller Mill Installation Concept

.jpg)

Raymond Roller Mill airswept vertical ringroll Qlar

½ 2in / 1050mm, the roller mill can produce particles ranging from coarse, granular products of approximately 10% R2000 micron 90% minus 10 mesh (10%R2000 microns) to as fine as 999% minus 325 mesh (0001%R44 micron) Applications A roller mill is most effective processing materials that are 5 or less on the Mohs scale of hardnessWrite better code with AI Code review Manage code changessbm/sbm roller mill installation sizemd at main2020年2月27日 7 Flaking Roller Mill MDFA Typ 608 Oats t/h * 1 – 4 Wheat t/h * 1 – 3,2 Rye t/h * 1 – 3,2 Spelt t/h * 1 – 3,2 Barley t/h * 1 – 2,5 Throughput capacity: High throughput capacity For every type of grain Typ 608 Roll diameter nm 600 Roll length mm 800 Maximum roll pressure kN 450 Weight kg 6500 Aspiration volume m³/min 30 An overview of the technical data for the MDFA Flaking Roller assetcdnbuhlergroupA Roller Mill RMI90 and Dynamic Separator Williams DF90 Roller Mill with 500 HP variable frequency AC drive, external right angle reducer, and dynamic separator B Cyclone Separator 20' 0" heavy duty cyclone collectors with ceramic liners, explosion vents, and 30" x 30" rotary valves, separate conveying/drying gases from product coalRoller Mills Installation Report Williams Crusher

sbm roller mill installation m8 arv м8арвmd

sbm roller mill installation m8 arv м8арвInfranorINFRAPOINTG H I J K L ABB 3BSER1 Millmate Operator Unit 400 PXAH402 SIEMENS4AM6142 8DDKSR Kuebler 2024年8月22日 Vertical Roller Mill The vertical roller mill (VRM) shown in Figure 4 is an air swept, mediumspeed, vertical pulverizer with integral classifier It pulverizes coal by applying hydraulicallyloaded grinding pressure through three grin ding rollers onto a rotating bed of coal Grinding pressure can be adjusted to account for variations in coalA Comparison of Three Types of Coal PulverizersOur bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency It is affordable to install and cost effective to operate over your cement plant’s lifetimeVertical roller mills FLSmidth Cement2024年1月15日 Particularly in the cement industry, ball mills have largely been replaced by roller mills for new plants [2], as they are compact, and the installation cost is smaller [3] The vertical roller mills are up to 40% more energy efficient than ball mills [4] The milled particles are typically a few microns to 100 μm in sizeOptimisation of the performance of a new vertical roller mill

聊城哪里有回收易拉罐分解的矿渣的

--华北地区的水泥厂分布图

--生石灰磨维修

--白云质石灰石生生流程

--西安方解石厂市场怎么样

--超细碳酸锂加工机器超细碳酸锂加工机器超细碳酸锂加工机器

--超精密球磨欧版磨粉机超精密球磨欧版磨粉机超精密球磨欧版磨粉机

--碳酸钙粉碎站Y3S1860滑石160

--怎么通过连续生石灰确定碳酸钙比例

--1300 300 重钙磨粉机雷蒙机

--PC80矿石磨粉机

--贵州石灰石碳酸钙磨粉机器

--硫磺生石灰氧化钙能产生二氧化硫吗硫磺生石灰氧化钙能产生二氧化硫吗硫磺生石灰氧化钙能产生二氧化硫吗

--西安磨辊磨粉

--残土粉碎

--MMD500矿石磨粉机粉碎能力

--芙蓉石挂牌价格

--万州五桥矿石磨粉机有卖的好吗

--碳酸钙石灰石粉碎机冶炼废渣矿石磨粉机与国外设备的差距碳酸钙石灰石粉碎机冶炼废渣矿石磨粉机与国外设备的差距碳酸钙石灰石粉碎机冶炼废渣矿石磨粉机与国外设备的差距

--铁虎牌微粉磨

--上海大白粉生产线厂家

--1.5米钻斗一抖土的一般重量1.5米钻斗一抖土的一般重量1.5米钻斗一抖土的一般重量

--高岭土有多大

--陶瓷膨润土粉磨设备

--多头自动磨石机

--哪里生产煤粉收集器

--露天煤矿应对恶略天气环保措施

--球磨机的价格

--陶瓷厂圧磨机

--烟煤无烟煤高岭土磨粉机

--